- All Products

- Food Processing Equipment

- Bandsaws - Industrial Meat

- Batter and Breading Machine

- Blenders - Mixers

- Blenders - Ribbon

- Mixers - Double Paddle (Double Action)

- Mixers - Industrial Dual Paddle Mixer- Blender

- Mixers - Industrial Vacuum Meat

- Mixers - Single Paddle

- Bowl Cutters - Choppers

- Cooking

- Cooking - Chilling

- Cooking Kettles

- Oven Cabinets - Baking

- Oven Cabinets - Cooking

- Oven Cabinets - Drying

- Oven Cabinets - Grilling

- Oven Cabinets - Smoking

- Pasteurization Chambers

- Cured Ham - Machinery

- Dicers Meat - Industrial

- Flakers - Frozen Block

- Forming Machine

- Grinders - Meat

- Grinders - Meat Industrial

- Injectors - Meat

- Meat Flatteners

- Meat Tenderizer

- Mixer Grinders -Meat

- Portioning Former

- Pre Breakers - Frozen Block

- Sausage Clipper

- Sausage Peelers

- Sausage Portion Cutter

- Sausage Portion Link Cutter

- Sausage Twister Linker

- Shredder - Meat

- Skewer Machine

- Slicers

- MHS Compact Vertical Slicer and Portion Control Machine

- Slicers - Bacon

- Slicers - Chicken Breast

- Slicers - Deli

- Slicers - Diagonal Cutting

- Slicers - Fixed Weight Slicing Machines

- Slicers - Frozen Guillotine

- Slicers - Grilled Meat

- Slicers - High Speed

- Slicers - High Speed Deli

- Slicers - Industrial Horizontal Slicers and Portion Control

- Slicers - Industrial Multi-Slicing Portion Control

- Smoke House's and Smoke Oven's

- Strip Cutters - Meat

- Stuffer - Hydraulic Piston

- Stuffers - Manual

- Vacuum Stuffers - Continuous

- Vacuum Tumblers Marinating

- Vacuum Tumbler - Continuous

- Vacuum Tumbler - Massaging

- Vacuum Tumbler - Non-Continuous

- Vacuum Tumbler - Table Top

- Vertical Mixers

- Food Packaging Equipment

- Automatic Shrink Tank Tunnels

- Bagging Machines

- Cardboard Tray Packaging

- Cooling Tank Tunnels

- Flow Wrapper

- Liquid Filler Systems

- Metal Detection / X-Ray

- Over Wrapping Machine

- Robotic Packaging

- Shrink Dip Tank

- Thermoforming

- Tray Sealing-MAP-SKIN Pack Machines

- Vacuum Chamber Packaging Machines

- Material Handling Equipment

- 240/400/600 LBS Industrial Meat Buggies

- Bins/Containers

- Buggy Lifts and Dumpers

- Lazy Susan's

- Meat Trucks and Vats

- Pallet Elevators

- Pallet Wrappers

- Hygiene and Sanitation Equipment

- Bakery Tray Cleaners

- Bin and Buggy Washer

- Boot Washing Systems

- Buggy Washing Machines

- Hand Washing and Sanitizing

- Industrial Tunnel Washers

- Tunnel Washers - Containers

- Tunnel Washers - Crates

- Tunnel Washers - Hanged Trays

- Tunnel Washers - Jeros

- Tunnel Washers - Pallets

- Industrial Washing Machine for Mesh Gloves and Aprons

- Knife Holder - Industrial

- Utensil Washer

- Food Equipment Consulting

- Parts

- Used Equipment

- Turn Key Project

- Cooker, Gas

- Cookers, Electric

- In Stock Now Quick Ship Equipment

- Join Our Team! Employment Opportunities

- Discontinued Equipment

Products

-

RAM Frozen Meat High-Speed Super Cutting Machine SHF-440

Bring ultra-thin, uniform slicing of frozen proteins to your line—with automatic infeed, high-speed servo control, and touch-screen simplicity. The SHF-440 delivers production-grade throughput while protecting cut quality and operator safety.

At-a-Glance Highlights:

Slices as thin as 0.5 mm with excellent uniformity for hot-pot, bulgogi, shabu-shabu, brisket, carpaccio-style items, and more.

High-speed output: 150–320 cycles/min to keep pace with industrial production targets.

Automat -

Mekitec MEKITEC ME.S2 Metal Detector for Food Processing Lines

MEKITM is an automated product quality control system using the latest

X-ray image processing technology. The system images the inside of food

products detecting foreign objects (e.g. metal, stones, glass, bones and dense

plastics), simultaneously ensuring the overall quality and traceability of food

production.

As like with other Mekitec X-ray systems, high moisture, salt content, or

different type of packaging materials (e.g. metal or aluminum) are not a

problem for the inspection.

MEK -

Promarks PRS-420 – Rollstock Thermoformer Machine

The PRS-420 Economy Thermoforming Machine is a versatile and easy-to-use machine that is perfect for businesses of all sizes. It can be used to create a variety of vacuum-sealed packages, including food, medical devices, and electronics.

The machine has a number of features that make it ideal for use in a variety of industries. These features include:

A touch control panel that is easy to use and navigate

A cross cut guillotine that allows for precise cuts

A rotating knife set that can b -

Talsa REA-ELECTRIC Automatic Cooking Kettle - 165 liter

Outstanding features

Thermal oil bath:

All models include an intermediate stainless-steel thermal oil chamber, internal expansion chamber, high-performance thermal fluid, and internal drainage tap.

The thermal oil chamber allows uniform heat distribution for better cooking and practically eliminates the possibility of burning foods as well as maintaining the initial heat for the following cooking, saving energy.

Time required to heat chamber filled with cold water from ±68°F to ±194ºC: -

Talsa REA-ELECTRIC Automatic Cooking Kettle - 250 liter

Outstanding features

Thermal oil bath:

All models include an intermediate stainless-steel thermal oil chamber, internal expansion chamber, high-performance thermal fluid, and internal drainage tap.

The thermal oil chamber allows uniform heat distribution for better cooking and practically eliminates the possibility of burning foods as well as maintaining the initial heat for the following cooking, saving energy.

Time required to heat chamber filled with cold water from ±68°F to ±194ºC: -

Talsa REA-ELECTRIC Automatic Cooking Kettle - 335 liter

Outstanding features

Thermal oil bath:

All models include an intermediate stainless-steel thermal oil chamber, internal expansion chamber, high-performance thermal fluid, and internal drainage tap.

The thermal oil chamber allows uniform heat distribution for better cooking and practically eliminates the possibility of burning foods as well as maintaining the initial heat for the following cooking, saving energy.

Time required to heat chamber filled with cold water from ±68°F to ±194ºC: -

Talsa REA-ELECTRIC Automatic Cooking Kettle - 505 liter

Outstanding features

Thermal oil bath:

All models include an intermediate stainless-steel thermal oil chamber, internal expansion chamber, high-performance thermal fluid, and internal drainage tap.

The thermal oil chamber allows uniform heat distribution for better cooking and practically eliminates the possibility of burning foods as well as maintaining the initial heat for the following cooking, saving energy.

Time required to heat chamber filled with cold water from ±68°F to ±194ºC: -

MHS Model PCE 65TM Horizontal Meat Slicer and Portion Control Machine

Compact. Space saving. Powerful. The PCE 65 TM table-based machine - Ideal for the butchery trade, supermarkets and canteen kitchens

A welcome addition to the table. With the PCE 65 TM, we reacted to customer requests and developed a practical, space-saving table-based machine, which offers the complete power of one of the large chop slicing machines.

The PCE 65 TM slices easily bone-in products such as meat, chops, necks or boneless products such as pork belly, roulades, roasts, sausages -

RAM Model SCD 300 Strip Cutter and Dicer

Today's fast-paced food industry, efficiency and precision are paramount. This why RAM offers the RAM Model SCD 300 Strip Cutter and Dicer for mid sized processors as well as restaurants and butcher shops at an exciting price point . This state-of-the-art equipment is not just a machine; it's a revolutionary tool designed to transform your meat processing operations. Engineered for both strip cutting and dicing, it offers unparalleled performance with its robust features and specifications.

K -

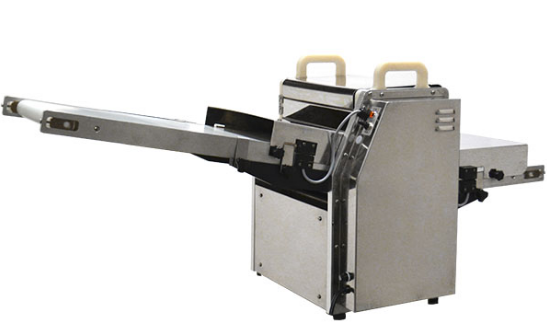

RAM HORIZONTAL TABLE TOP MEAT SLICER TP-30

Introducing the Horizontal Chicken Slicer TP12-30:

Revolutionize your food preparation with our state-of-the-art chicken slicer. Designed with efficiency and hygiene in mind, the TP12 is engineered entirely from stainless steel, ensuring durability and ease of cleaning. Compact and ergonomically designed, it fits perfectly even in small spaces and simplifies operation without compromising on performance. Capable of processing up to seven products per minute, it's not just limited to chicken; e