Products

Thompson Meat Machinery Model 4200 Meat Mixer Grinder

Thompson Meat Machinery Model 4200 Meat Mixer Grinder

Description

The Thompson Meat Machinery Model 4200 Meat Mixer-Grinder is completely weld sealed both inside and out. This machine is perfect for high volume butcher shops, large wholesalers and industrial plants. The Thompson Meat Machinery Model 4200 Meat Mixer-Grinder comes in low loading form for easy loading capability. You can even request a raised machine. The Thompson Meat Machinery Model 4200 Meat Mixer-Grinder Offers Hopper Capacities ranging from 400 lbs to 800 lbs of fresh meat.The standard height Thompson Meat Machinery Model 4200 Meat Mixer-Grinder machines incorporate a heavy gauged domed lid with an open grilled section for ingredients adding or viewing during the mix cycle. An ingredient/ liquids pouring channel is also offered as an option.

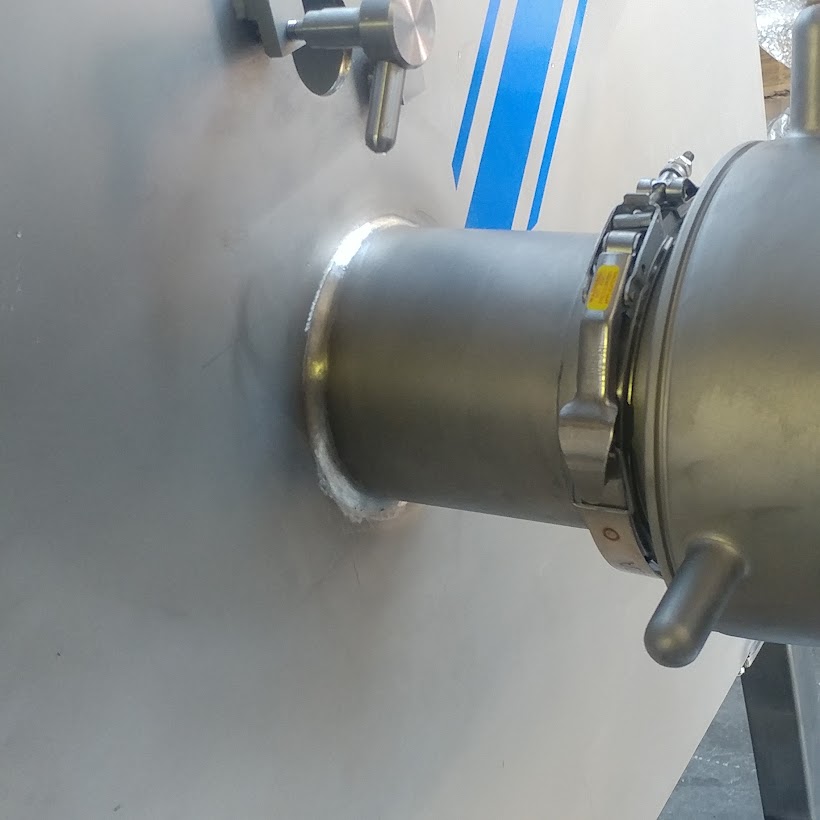

Heavy duty stainless steel mixing paddles, mincing barrel, feed screw and lock ring are standard construction on these renowned machines. The Thompson Meat Machinery 4200 Meat Mixer-Grinder series has been designed and developed to the high standards of safety and finish demanded by CE / USDA and GS regulations. All models specifically incorporate the **"SMART DESIGN" mixing bowl and paddle. The Thompson Meat Machinery Model 4200 Meat Mixer-Grinder is fully made of finished and smooth hygienic surfaces, panels and welds to achieve a clean bowl on product discharge. All this makes for an easy, fast and hygienic cleaning process at the end of production.

RAM Manufacturing Equipment is located in Corona, California. We offer training, installation, service and parts for all the machines we sell. Including the Thompson Meat Machinery Model 4200 Meat Mixer-Grinder and many others.

Call, E-mail or visit us today for more information!

235 Benjamin Dr. Suite 102

Corona, CA 92879

951-734-8152

info@ramaxwell.com

Features

- Constructed from heavy gauge Stainless Steel and fully seamed welded

- Stainless Steel feed-screw and paddle

- Removable Stainless Steel mixing paddle

- Lid with inspection slots to allow product to be added during operation

- 9.2kW Mince Motor

- Pneumatic Foot Pedal allows hands-free operation

- Ingredients and liquid pouring channel to lid

- Feed-screw knife and plate carriage

- heavy gauged doomed lid with an open grilled section

- "Smart Design" mixing bowl and paddle

- smooth hygienic surfaces

Optional Features

- Gemini System allows 2 machines to be joined for continuous 1st and 2nd cut operation

- Stainless-Steel elevating stands

- Variable Speed Drives

- Controllable Mix / Grind Cycles

- PLC pre-set Programmable Control

- Product Temperature Readout

- GEMINI Connection / Systems

- Pneumatic Lid Operation

- CO2 Cooling

- Bone Elimination System

- Feed-screw / Knife and Plate Trolley

- Ingredients and Liquid Pouring Channel to Lid

- Load Cells to Mixing Bowl

Specifications

| Model | Model 4200-56 |

|---|---|

| Voltage | 230V / 60 Hz / 3 Ph |

| Head Size | 56 |

| Hopper Capacity | 600 lbs |

| Mix Capacity | 400 lbs |

| Grinder Motor | 2.2 kW |

| Mixer Motor | 15 kW - 2 Speed |

| Transmission | Helical |

| Primary Cut "56" 1/2" / 12.7 mm Plate per Hour | 8,818 lbs / 4,000 Kg |

| Primary Cut "56" 1/2" / 12.7 mm Plate per Minute | 147 lbs / 67 Kg |

| Secondary Cut "56" 1/8" / 3.175 mm Plate per Hour | 4,409 lbs / 2,000 Kg |

| Secondary Cut "56" 1/8" / 3.175 mm Plate per Minute | 73 lbs / 33 Kg |