Products

Thompson Meat Machinery 5500 Twin Paddle Mixer Grinder

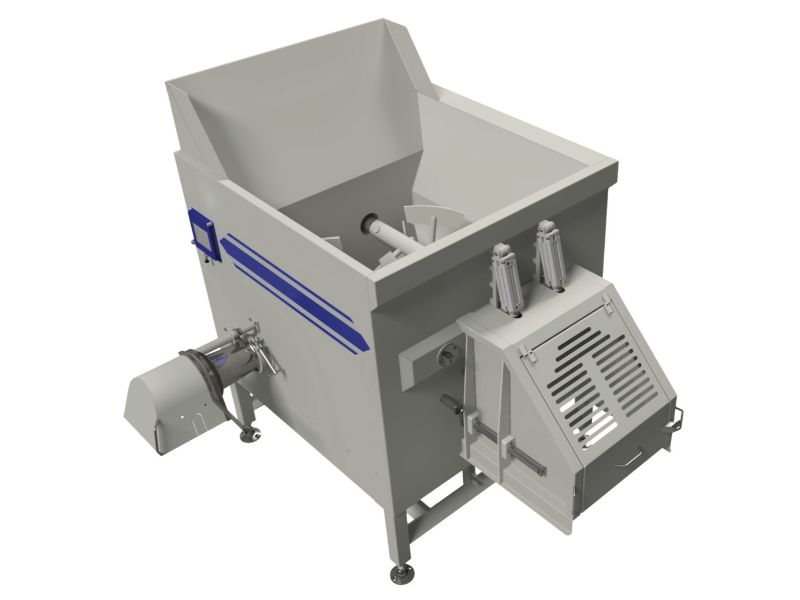

Thompson Meat Machinery 5500 Twin Paddle Mixer Grinder

Description

Introducing the Thompson 5500 Mixer Grinder, a robust and versatile solution designed for high-volume meat processing operations. Available through RAM Manufacturing Equipment, this industrial-grade machine comes in two configurations to meet diverse production needs.The Thompson 5500 Mixer Grinder's two Variatios:

Inspection Mirror Model: Features an operator mirror for enhanced visibility and control during processing.

or

Discharge Chute Model: Equipped with a pneumatically controlled discharge chute for efficient product removal without re-grinding.

🔧 Key Features & Specifications

Twin Paddle Mixing System: Overlapping twin-shaft paddles ensure thorough mixing throughout the bowl, promoting uniformity in the final product.

Smart Bowl Design: The bowl's shape and volume are optimized for efficient mixing and product discharge, minimizing mixing cycles and temperature increases.

Feedscrew Design: Operates at a right angle to the mixing bowl and paddle, reducing the feedscrew length inside the bowl. This design maximizes production output rates up to 8000 kg/hour on the first cut through a 10 mm hole plate and 7500 kg/hour on the second cut through a 3 mm hole plate.

Material Construction: Crafted from high-quality 304 stainless steel, ensuring durability and compliance with food safety standards.

Motor Options: Standard 22 kW gear motor mince drive, with an upgrade option to a 30 kW gear motor drive for processing frozen meats down to -12°C.

Mixing Capacity: Volume capacity of 600 liters to the top of the paddles, allowing effective mixing of 500 kg batches.

📦 Configuration Options

1. Inspection Mirror Model

Provides operators with enhanced visibility into the mixing process, facilitating better control and quality assurance.

2. Discharge Chute Model

Features a unique product discharge door that allows the bowl contents to be emptied without passing through the feedscrew and cutting system. This design maintains the meat's integrity, producing a juicier product with better mouthfeel and bite.

🏭 Ideal Applications

High-Volume Meat Processing: Suitable for large-scale operations requiring efficient mixing and grinding.

Sausage Production: Ensures consistent texture and flavor in sausage manufacturing.

Burger Patty Formation: Provides uniform mixing essential for quality burger patties.

For more information or to request a quote, visit the Thompson 5500 Twin Paddle with Inspection Mirror or Thompson 5500 Twin Paddle Discharge Chute product pages.

Experience the efficiency and reliability of the Thompson 5500 Mixer Grinder—engineered for excellence in meat processing.

Features

Specifications

| Model | 5500 - Twin Paddle Integral Hopper | 5500 Twin Paddle Inspection Mirror |

|---|---|---|

| Bowl and hopper combined capacity: | 1,135 Litres (300 gallons) | 1,135 Litres (300 gallons) |

| Volume at top of Bowl: | 900 Litres (240 gallons) | 900 Litres (240 gallons) |

| Volume at top of Paddle: | 600 Litres (160 gallons) | 600 Litres (160 gallons) |

| Mince motor: | 22 kW (30 hp) with option of 30 kW (40 hp) | 22 kW (30 hp) with option of 30 kW (40 hp) |

| Mixer motor: | 9.2 kW (12 hp) | 9.2 kW (12 hp) |

| Ejector: | Pneumatic | Pneumatic |

| Loading Height: | 2117mm (83.3") | 2117mm (83.3") |